Industrial printers

Industrial printers for printing on cardboard

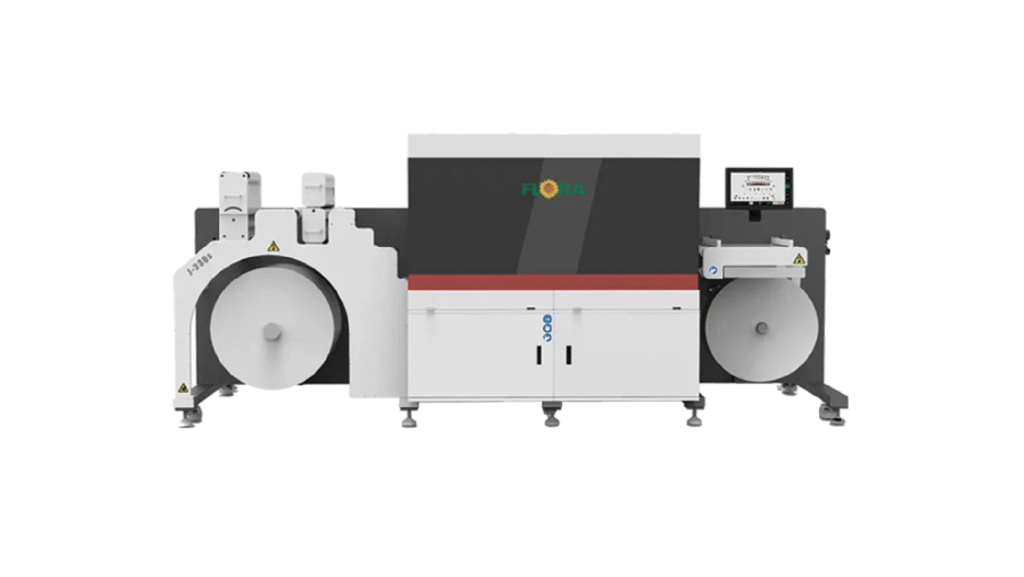

Flora industrial printers for marking cartons

Cardboard packaging is used in every branch of industry. They are used to store and store various types of products, they also protect them from damage during transport. In order to easily identify the contents of cardboard packaging, it is necessary to mark them appropriately. The print can include text, bar code, date or logo - it is important that it is legible and durable. Packaging can be provided with self-adhesive labels, but printing directly on the cardboard turns out to be a more effective solution. It allows you to avoid waste from labels, and also positively affects the recycling of waste paper. Flora industrial plotters enable efficient marking of most of the cardboard materials available on the market. The resulting prints are not only durable, but also precise and aesthetic.

Industrial printers Read More »